The thing about machinery and infrastructure is that they need constant and regular maintenance, not just when they break down. That’s why you send your car in for a service now and then — to prevent or minimize breakdowns. That’s called preventive maintenance.

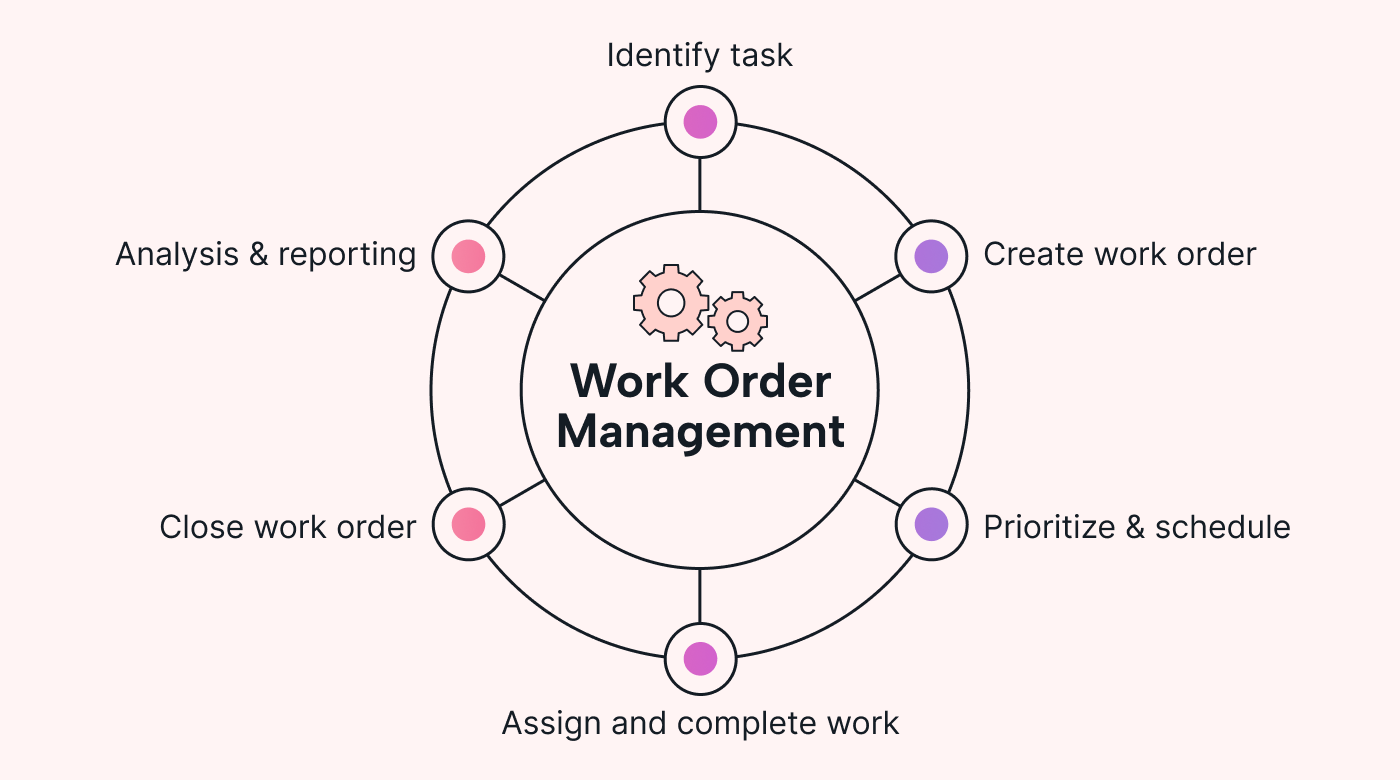

And when you’re maintaining equipment, machinery, or infrastructure, you’ll need work orders to help you track and manage the process. That’s because every unique piece needs special skills to keep it in good working order. It might be a technician, a mechanic, an electrician, a plumber, or any other specialist.

That’s where work orders come in. They’re formal requests for maintenance, repair, or servicing and contain specific instructions for the maintenance team. Work orders usually also have details of who authorized the job, who’s assigned to it, the extent of the work, and an expected timeline. They can also include comments from users or customers.

What is a work order management system?

In the old days, a work order management system was largely manual. Technical people would be given a piece of paper with the details and the authorization. That would empower them to draw or purchase the necessary spares and consumables.

But bits of paper floating around are difficult to control, and we use our computer systems these days. It’s far more efficient and easier to track and manage. These work order management systems also improve communication and eliminate the problem of missing paperwork. They centralize and streamline the whole process.

CMMS vs. work order management

A work order management system shouldn’t be confused with a Computerized Maintenance Management System (CMMS). It’d be like comparing a steak to an entire meal. While the CMMS can generally do everything a work order management system can, the opposite isn’t true.

Work order systems are designed to help maintenance departments assign work efficiently and ensure it’s completed on time. Good systems will keep detailed work histories for each piece of equipment. They’ll also provide real-time updates on ongoing work and integrate with handheld mobile devices.

A good CMMS will do all of that and then some. Among other things, it’ll:

- Alert staff to preventive maintenance needs

- Manage an inventory of consumables and parts

- Facilitate procurement processes directly

- Manage and balance maintenance budgets

- Track and document worker performance

- Make extensive use of GPS tracking and IoT functionality.

Whether you’re looking for a CMMS or a work order management system is something only you’ll know, so we’ve included both in our list of solutions.

|

Features you should look for

If it’s just a work order management system you’re looking for, there are several key features you should want that may not be available in all of them. The first must-have feature is the ability to categorize and prioritize work orders.

Your system must allow you to prioritize critical jobs more to avoid losing them in the maintenance backlog. This feature will help your maintenance managers avoid wasting key resources on relatively low-importance maintenance tasks.

Other features you should look for include:

- Notifications

- Work requests

- Work order creation

- Inventory management

- Mobile access

- Reduced cost of maintenance

- Work orders assignation (time, place, assignment)

- Integration with ERP systems, payroll, and other business systems

- Predictive maintenance

- Scheduling

- Work order calendar view

- Maintenance checklists

- Performance monitoring.

9 work order management tools to consider

In deciding what you need and which system to choose, you should take a good look at your business and figure out what it is that you need from the features listed above.

It may be that a relatively simple work order management system will work for you. Or, you may decide you need a bit more, and a full-functioned CMMS is a better option. Either way, here are 9 tools for you to consider.

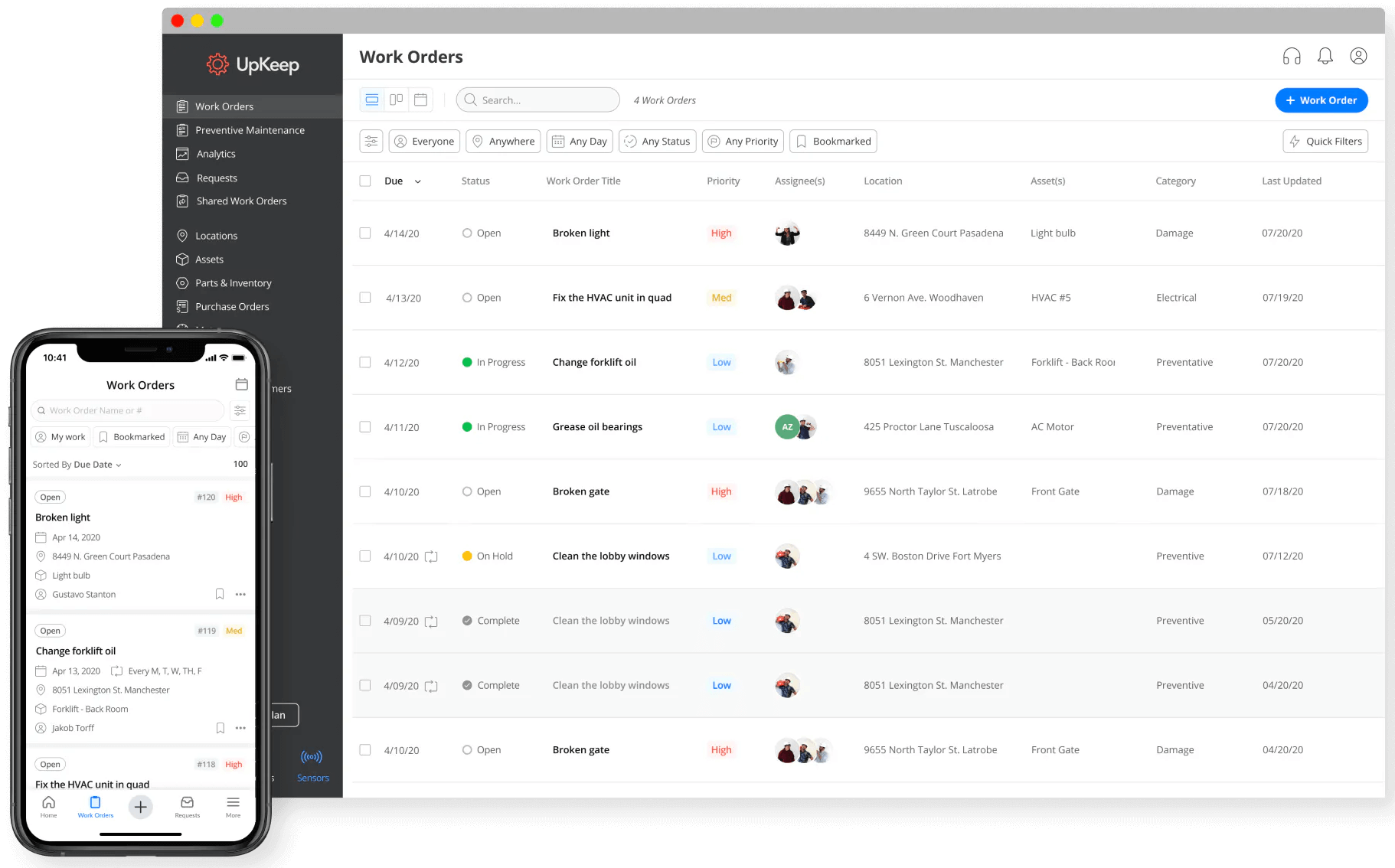

UpKeep

This work order management tool is best known for mobile optimization and synchronization. It makes prioritizing and assigning tasks easy and allows you to track time and costs within each work order.

The tight mobile integration means push notifications are more immediate, allowing you to attach manuals and instructions to work orders. This gives technicians and specialists mobile access to those documents.

The result is improved productivity and reduced equipment downtime. UpKeep also automates data collection and reporting, which significantly supports operational decision-making.

Pros:

- Streamlined maintenance operations and schedules

- Simplified workflows

- Increased productivity

Cons:

- No free version available

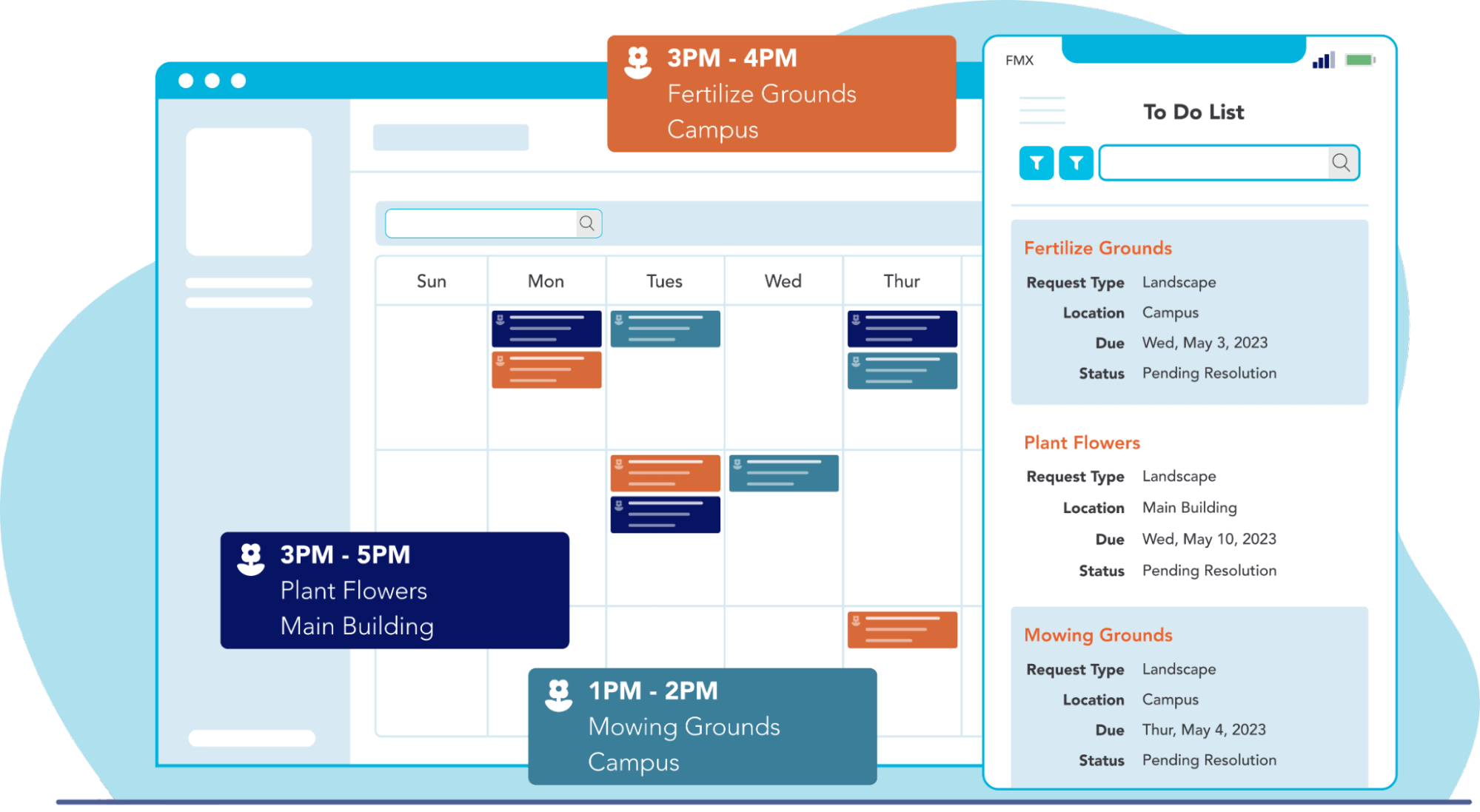

FMX

As software systems become more ubiquitous, they’re becoming more specialized and that’s what you get with this CMMS. FMX began as a comprehensive facilities management solution, and the company branched out into related specialties from there.

Facility managers designed this cloud-hosted product for facility management. It’s perfect for streamlining maintenance tasks while keeping track of labor and costs. It helps you to save time by automating routine processes and provides extensive management reporting.

Pros:

- Streamlines work orders based on your prioritization

- Asset management features help you save on unexpected repairs, breakdowns, and asset replacement

- Inventory tracking linked to work orders with notifications when items are running low.

Cons:

- Lacks an integrated mobile app

- Complicated pricing model based on number of users, features and custom workflows enabled.

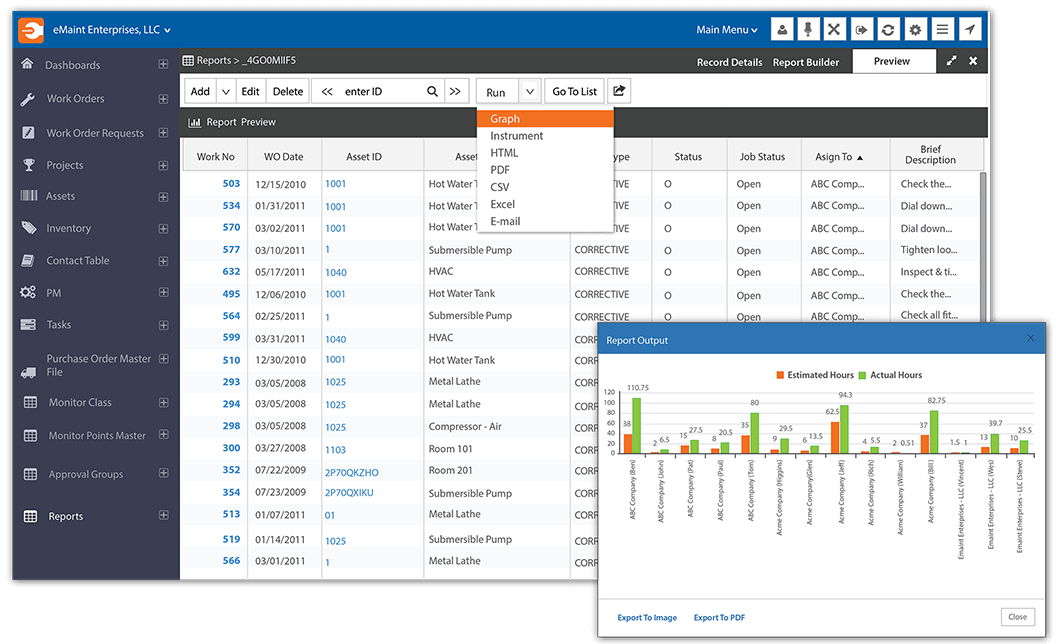

eMaint

This fully-fledged CMMS is better known as an Enterprise Asset Management (EAM) system. To make it even more interesting, it comes from a company better known for testing and measuring equipment, Fluke.

Still, the cloud-based eMaint software is the real deal. It offers work order management, workflow optimization, notifications, inventory tracking, and automatic scheduling of predictive and preventive maintenance.

It also lets you track, capture, store, and share historical asset performance data. You can use that information to prolong and extend the life of your equipment and machinery. eMaint is also customizable and configurable, making it suitable for small or growing businesses.

Pros:

- Highly configurable workflows

- A wide range of customization options

- Very easy to use.

Cons:

- Difficult to track component failure through machine history.

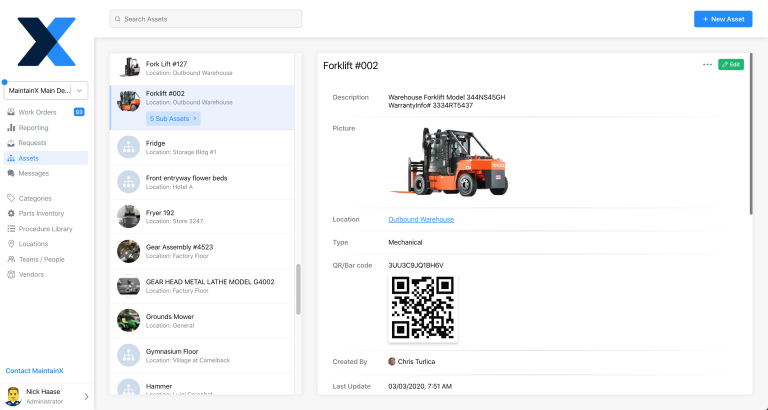

MaintainX

Some software solutions are designed to be in the cloud, supporting access from various mobile devices. MaintainX simplifies work order and task management. It includes AI capabilities that analyze historical data and patterns to suggest optimal workflows.

The software also features proactive anomaly detection, including unexpected equipment behavior and maintenance irregularities. It’s easy to use and includes a range of templates for recurring maintenance tasks. This improves consistency and task execution efficiencies.

Pros:

- Request portal simplifies maintenance request management

- Downtime tracking for greater control of operational inefficiencies and identification of patterns

- Allows recurring work orders on a shared calendar.

Cons:

- Limited function in off-line mode.

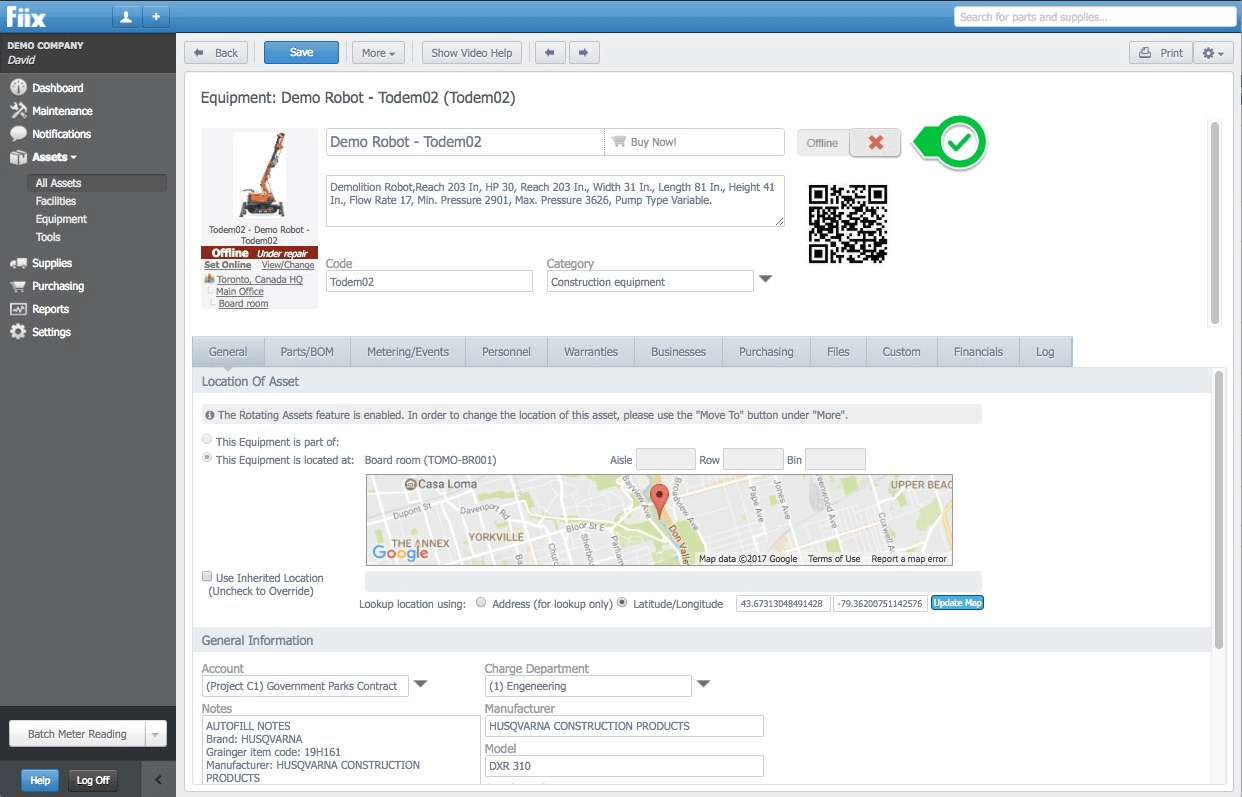

Fiix

Another modern product built in the cloud and for access on the go, Fiix is a full-featured CMMS solution that remains budget-friendly. Developed by Rockwell Automation, it features asset, inventory, and work order management.

This product integrates easily with various corporate IT systems, including IoT solutions, and offers AI-driven insights and automation. It also gives you a complete view of current work, parts, costs, schedules, and KPIs — all accessible wherever you are.

Pros:

- Streamlined work order management

- AI-powered automation and advanced analytics

- Robust access, control, and integration of work order procedures and data.

Cons:

- Customization options are limited

- An all-or-nothing pricing structure.

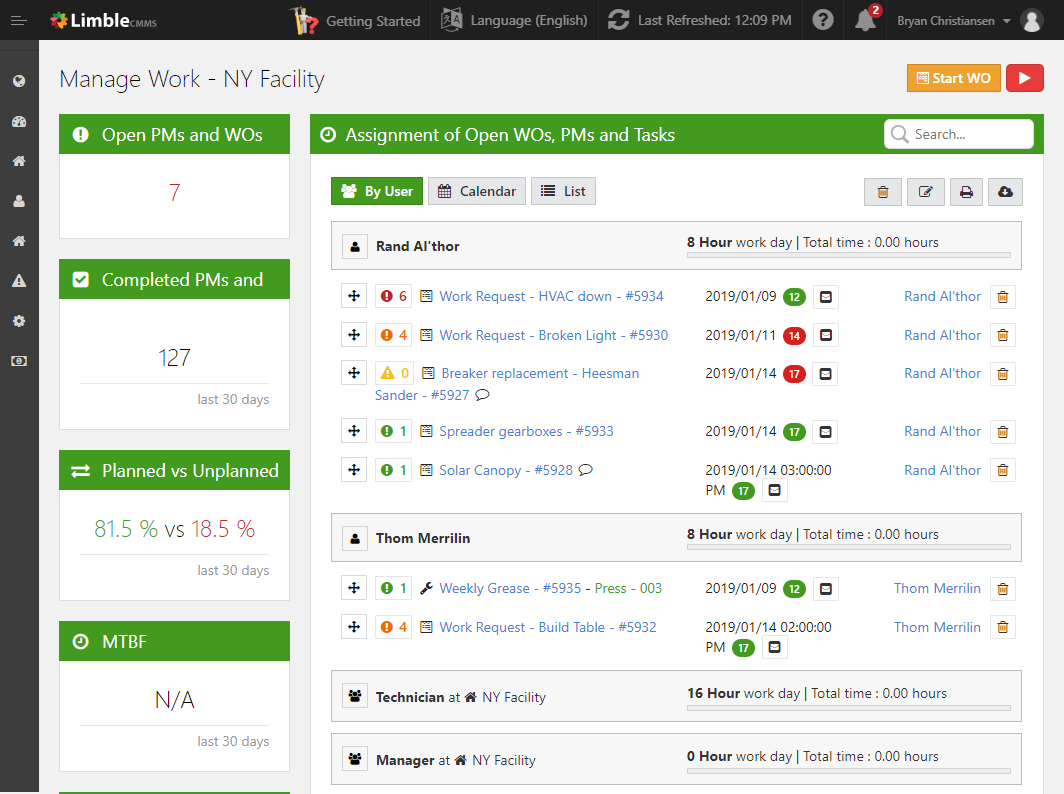

Limble CMMS

Well-suited to mid-size businesses, Limble CMMS is a customizable system that helps you optimize your maintenance tasks. It tracks data, including parts usage, work completed, and time taken, and provides automated maintenance reports.

It offers insight into the cost and efficiency of your maintenance operations, which helps your maintenance managers with their planning. It also provides a full suite of features: asset tracking, work order management, preventive maintenance planning, inventory control, mobile access, personnel management, and equipment maintenance histories.

Pros:

- Capture and store signatures digitally

- Streamlines maintenance activities

- Extensive asset management functionality.

Cons:

- No offline version and mobile app hard to use.

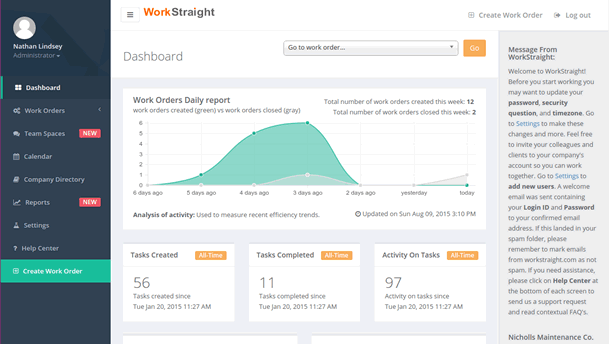

WorkStraight

A web-based work order management tool marketed as a Software-as-a-Service (SaaS) solution that offers the features you’d expect. WorkStraight lets you create work orders, do task assignments, monitor progress, enable team communication, and provide notifications.

Its biggest advantage is simplicity of use, making it easy for your team members to navigate and complete the assigned jobs. It also integrates well into a modern business, allowing smooth workflow management.

Pros:

- Customers can create and track their own work orders

- View work orders by customer and link work orders together

- No credit card required for a free 30-day trial.

Cons:

- The dashboard isn’t customizable.

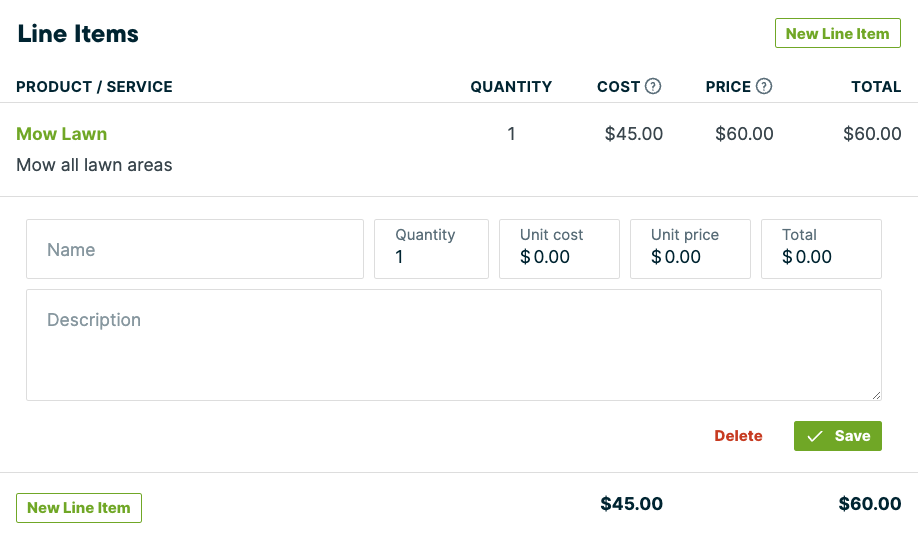

Jobber

Sometimes, you’ll think that you need a work order management system when you need a field service management solution. That’s when you should look at Jobber. It’s a SaaS offering that works well in any business that needs to respond to service requests in the field.

It does most things that a typical work order management system does and has some unique extras. You can build custom forms with checklists that you can share with customers. Jobber also has a nifty color-coded scheduling board and a map view to see where each team member is at any given time.

Pros:

- Creates and sends branded professional quotations

- Real-time scheduling and dispatching, status updates from job site

- Customer-facing hub lets clients make their own bookings and payments

Cons:

- Employees can’t be paid through Jobber.

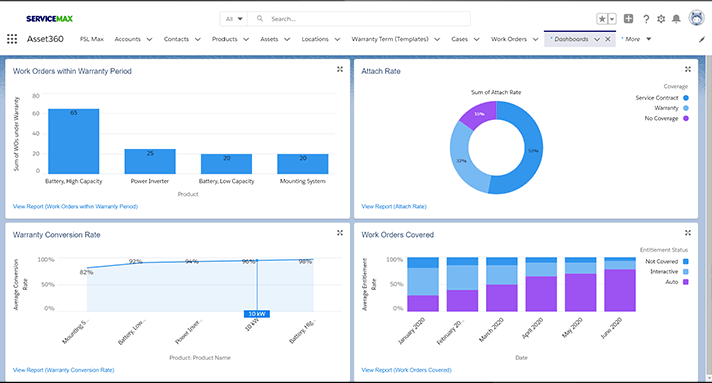

ServiceMax Asset 360

This is another work order management system that’d be better described as a field service management tool. ServiceMax Asset 360 is quite similar to Jobber but provides service process management to improve productivity and compliance. It’s been optimized for small businesses, but is also used by medium-sized and large organizations.

Another key difference is that it’s built on top of Salesforce Field Service. It uses a rules-based engine to help operators prioritize, match, schedule, and monitor work orders. Parameters considered include SLA (service level agreement) details, preferred technology, and skills. The product also includes a mobile app for field personnel to complete work orders, get customer signatures on service reports, and much more.

Pros:

- Service automation and standardization

- IoT integration for asset monitoring and analytics

- Contractor and spares management.

Cons:

- No free version or free trial.

Could this be overkill?

When you think about it, all these tools may offer much more than you need. Work order management is really just the management of tasks to be performed by internal or external specialists. They do the work. You just need to make sure they know what to do and when you need it done.

All the systems listed above can do that and a whole lot more. The question you must ask yourself is: How much of the ‘whole lot more’ do you need? The answer may surprise you, but it could also save you money.

Motion may be all you really need

Motion Task Manager might be just the ticket if you’re dealing with a small number of machines or pieces of equipment. It’s an AI-powered tool that helps you manage, organize, and prioritize your tasks. It’s basically a to-do list on steroids.

But if you need to manage a bit more than that and your team is more than just a few people, the Motion Project Manager app could be better for you. It lets you plan less and do more by doing a lot of the work for you:

- Adding work to your team member's calendars

- Measuring how much your team can accomplish

- Creating a prioritized, custom schedule for every team member

- Automating 90% of project planning.

If that sounds like what you need right now, try Motion for free for seven days!