Given time to make adjustments, you know your business could produce quality products and services. But, in today’s fast-paced, consumer-driven market, time is in short supply.

Customer expectations have changed. They don’t only expect speedy delivery, but a consistent experience every time they do business with you. Salesforce found that 83% of consumers say they’re more loyal to companies that provide a consistent experience.

You know that you need a process to improve the quality of your deliverables, but you’re not sure which or how to get started.

In this article, we’ll dive into the fundamental principles of total quality management (TQM). We’ll explore its benefits, key principles, and implementation strategies for businesses struggling to achieve excellence in today’s competitive landscape.

Let’s get started.

What is total quality management?

Total Quality Management enables you to provide top-notch products and services by constantly aiming for improvement. It's a systematic approach to scrutinize every step in your business processes, from start to finish, to maintain a high level of excellence. By seeking ways to enhance your operations, you can offer the best to your customers, driven by unwavering standards of quality. Implementing Total Quality Management can significantly transform your business operates, yielding notable advantages.

Here are just three of the ways TQM can transform your business:

1. Improve the quality of your service delivery

One of the primary purposes of TQM is to improve the quality of your services by improving the processes that make up those services. This means making sure that everything you do meets the highest standards while executing them in the most efficient way possible. You can increase your customer loyalty, and as a result, your revenue, just by focusing on quality control and improvement.

For example, say you run an accounting firm. TQM in your business would mean making sure that how you do taxes for your customer is the most efficient way to perform this service.

To do this, you'd review your current processes and see where your team runs into roadblocks. You could also survey your customers to see how they feel about your business and your services. Brainstorm with your team to see if changes can be made to your existing processes to save time while giving your clients a higher level of service.

2. Eliminate waste and improve efficiency

Another great thing about TQM is that it helps remove waste and inefficiencies. This means cutting anything that doesn't add value (or slows things down).

In the accounting practice, this could be as simple as going paperless or having your clients email their documents before appointments.

If you're thinking there has to be an easier way to do this, you're probably right. TQM helps you find that more straightforward way.

3. Create a culture of continuous improvement

TQM also creates a culture of continuous improvement.

In your business, you should always look for ways to improve. Never settle for just being good enough. By constantly striving for improvement, you can stay ahead of the competition.

Also, every single member of your team should be encouraged to seek and recommend improvements.

For example, one of your accountants might find that there is a way to integrate your client's accounting software with your own to streamline bookkeeping. Not only has your accountant saved time by being able to access the client's information, but it's also possible they have found a new revenue stream for your business. If you can sell your clients the same software you use, you could probably earn an affiliate commission. Bonus!

When you implement TQM, it makes quality an essential part of your company's culture. It becomes something that everyone cares about and works towards. This way, quality isn't just a one-time thing but a part of everything you do.

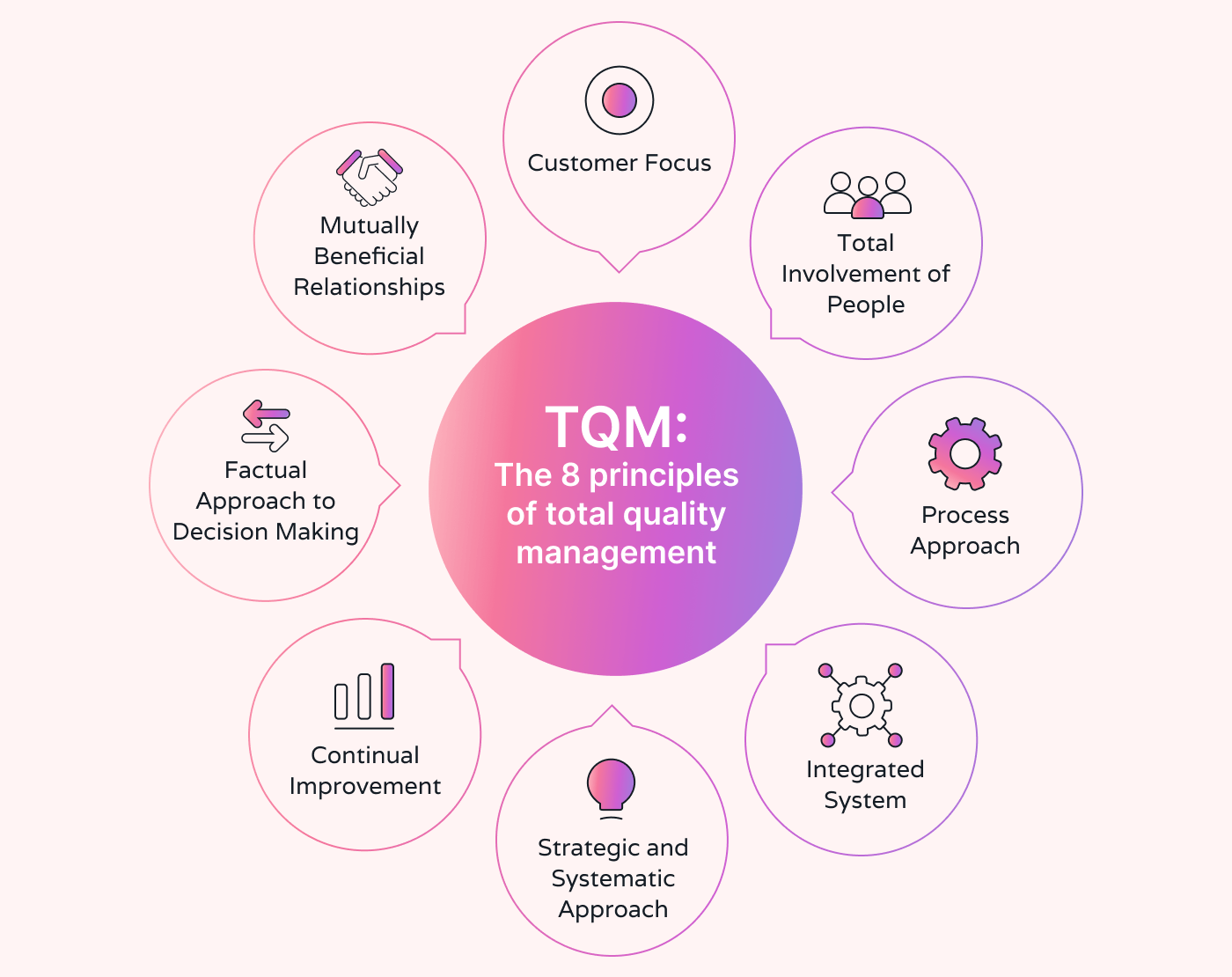

The eight principles of TQM (and how to implement them)

Now that what TQM is, let's look at the eight principles of TQM and how to implement them in your business.

|

The core principles are:

1. Customer focus

Customer focus means putting customer experience at the center of everything your business does. It’s about understanding what customers want and need and then delivering products and services that make them happy.

To make customer focus a reality in your business, here's what you can do:

|

Understand your customer’s needs and expectations:

- Use market research, surveys, and feedback to learn what your customer base likes, dislikes, and wants.

- Analyze customer data to find patterns and trends that can help improve your products and services.

Prioritize customer satisfaction and delight:

- Set clear goals and performance indicators that measure customer satisfaction.

- Regularly check how satisfied your customers are with surveys and reviews.

- Take immediate action to fix any problems.

Involve customers in decision-making and improvement processes:

- Create opportunities for external customers to give input and ideas, like feedback forums or advisory boards.

- Develop a process to review and consider customer feedback when making decisions.

2. Total involvement of people

Total involvement of people means prioritizing employee morale (and involvement) by empowering staff to make a difference.

It recognizes that every employee has valuable insights, ideas, and contributions that can contribute to the organization's success and improvement efforts.

To make total involvement of people a part of your business, here’s what you can do:

Encourage open communication and idea-sharing:

- Provide ways for employees to share their ideas and feedback, like suggestion boxes or team meetings.

- Create a company culture where everyone feels comfortable speaking up and sharing their expertise.

Provide training and development opportunities:

- Offer regular training to help employees improve their skills and knowledge.

- Encourage employees to work on different projects or try new roles to expand their understanding of the business.

Empower and delegate authority:

- Give employees the authority to make decisions related to their work.

- Encourage them to solve problems independently and provide the resources they need.

|

Focusing on customers and increasing employee commitment can create a business that delivers excellent products and services (while making everyone feel valued and essential).

3. Process approach

The process approach is all about seeing how different parts of a business are connected (and work together). Instead of focusing on individual tasks, the process approach looks at the process as a whole.

To give this a go in your business, here's what you can do:

Identify and map key processes:

- Figure out the most critical processes that impact the quality of products or services.

- Create visual maps or flowcharts to show how each process works and who is responsible for what.

Analyze and optimize processes:

- Look for areas where things can be done more efficiently or where you can eliminate waste.

- Use problem-solving methods like Lean Six Sigma to optimize processes.

Monitor and measure process performance:

- Set goals (and measure) to see how well each process performs.

- Keep track of progress and use the data to find improvement areas.

4. Integrated system

The integrated system principle means bringing your processes and workflows into one (integrated) ecosystem. In your business, this might look like Slack, Google Drive, and your project management software all integrated so you can streamline workflows.

Integrating your tools can seem daunting at first. Here are a few steps to get you started:

Establish a quality management system:

- Create a project board in a tool like Motion to track all of your improvement activities in one place.

- Make sure everyone can access the quality policies and procedures by documenting them in a centrally accessible place (such as a Motion project board).

Foster cross-functional collaboration:

- Encourage different teams and departments to work together and share ideas.

- Have regular meetings where people from different parts of the business can discuss challenges and share their expertise. Did you know Motion has an auto-scheduling feature?

Standardize processes and practices:

- Find the best ways of doing things and make them standard across the organization.

- Document clear instructions for how things should be done in your business.

5. Strategic and systematic approach

The strategic and systematic approach means approaching quality in a planned and structured way.

To implement a strategic and systematic approach, here's what you can do:

Align quality objectives with strategic goals:

- Set quality goals that support the strategic goals of your business.

- Identify specific quality objectives that support and align with these strategic goals.

- Make sure these goals are specific, measurable, achievable, relevant, and time-bound (SMART).

Develop a quality management plan:

- Create a plan that outlines the strategies, actions, and resources needed to reach your quality goals.

- Assign responsibilities and make sure everyone knows what they need to do.

Integrate quality into strategic decision-making:

- Consider quality when making important decisions for your business.

- Make sure everyone understands how quality contributes to long-term success.

6. Continuous improvement

The continuous improvement principle means always looking for ways to improve. Take a proactive and systematic approach to identify areas for improvement.

To build a culture of continuous improvement:

Establish a culture of innovation and learning:

- Encourage employees at all levels to come up with ideas for improvement.

- Create an environment where it's okay for employees to try new things and learn from mistakes.

Implement structured improvement methodologies:

- Adopt proven improvement methodologies such as Lean, Six Sigma, or Kaizen to guide systematic improvement efforts.

- Train employees on these methods so they can contribute to making things better.

Collect and analyze data for informed decision-making:

- Collect and analyze information to see what can be improved.

- Use data to guide your decisions and measure the effectiveness of your changes.

7. Factual approach to decision-making

The factual approach to decision-making means making decisions based on reliable information.

To make factual decision-making a reality in your business, here's what you can do:

Collect and analyze relevant data:

- Decide which metrics mean the most in your decision-making and prioritize tracking these in detail.

- Make sure the data you collect is accurate and trustworthy.

Emphasize evidence-based decision-making:

- Encourage everyone to use facts and evidence when making decisions.

- Avoid relying on assumptions or opinions.

- Train employees to interpret and use data effectively to inform their decision-making.

Establish decision-making frameworks:

- Create guidelines for how decisions should be made.

- Make sure everyone knows their role in the decision-making process.

8. Mutually beneficial relationships

The principle of mutually beneficial relationships means building strong partnerships with suppliers and other stakeholders.

|

Building better relationships takes time, but here are a few things you can do to get started:

Foster open and transparent communication:

- Keep the lines of communication open with suppliers and other partners.

- Listen to their feedback and suggestions.

Collaborate with stakeholders for shared goals:

- Find common goals and work together to achieve them.

- Involve stakeholders in decision-making and problem-solving.

Recognize and invest in stakeholders' development:

- Show appreciation for the contributions of suppliers and other stakeholders.

- Support their growth and encourage continuous improvement.

Motion and TQM: Automate operations to easily implement TQM principles in your business

When you're constantly under pressure, you can't see the forest for the trees. You know you need to make changes, but it's so hard to know where to start.

A TQM business management approach can help you build a culture of improvement that takes the pressure off.

And don't think you have to fix everything yourself. Lean on your team and build quality systems to make small changes that lead to big results.

Automate TQM processes in your business using AI-driven project management software.

- Build your QMS directly in Motion projects with all SOPs and manuals located in one place.

- Auto-schedule your meetings with team, clients, and suppliers using automated Meetings.

- Assign improvement tasks to the team using auto-scheduling tools like Motion's Intelligent Calendar.

- Centralized documents in Motion, which integrates with Google Drive.

- Foster collaboration using Motion's Kanban boards.

TQM can be a game-changer, but you don't have to go at it alone. Try Motion free today.