Two of the biggest requirements of any project are to finish on time and within budget. But waiting until the end to check will probably be too late and cost more than planned. That’s why project managers pay close attention to costs, measuring them for performance against budget using tried-and-tested tools.

An estimate at completion formula is one of those tools. It lets you estimate the total project cost at various points and compare it to the project budget. It seems obvious: You start with the actual cost of the work performed so far and add the expected cost of completing the project.

But it’s not quite that simple. There’s not just one estimate at completion (EAC) formula. There are four. In this article, we discuss how your choice of which formula to use depends on your financials, resources, availability of data, the state of your project, and how far along you are with it.

Benefits of using EAC

Even the most carefully planned project will hit snags. And those unforeseen challenges often have a financial aspect, which could blow out the project budget. Project managers must constantly balance competing priorities while keeping a sharp eye on costs. That’s where you’d need tools like these EAC formulas.

By keeping an eye on EAC and calculating it periodically, you always know how much leeway you have in your project budget. And if you know that, you also see how any changes needed will affect the project cost. That puts you in a better position to react positively when the unexpected happens.

Re-calculating your project EAC helps you set and manage stakeholder expectations and makes it easier to identify areas where you might be off-track and adjust accordingly.

It’s easier to make well-informed decisions when you know exactly how much money is involved.

Why EAC changes during a project

Imagine that you’re on a three-day road trip with your family. A couple of hours into the journey, something goes wrong with your car. The first thing you do is assess the extent of the problem. How bad is it? What do we need to fix the car? What resources do we have to do it? Should we turn back and do the trip another time?

These are the questions that’ll likely flash through your mind. But if the same thing happened later in the trip, some questions would have different answers. For example, some financial resources will have been used up on the trip.

It’s the same with projects. EAC is a formula to track your project costs against the budget. If, at any point, the cost of work performed is more than what was planned, it calls for an EAC check. You use the formulas to figure out how and why your EAC changed. And if the EAC doesn’t change, you’ll have the calculations to explain why not.

Components of the formula

Before we delve into the EAC formulas themselves, we need to consider the bits of data we’ll need to make our calculations. What are they? Where do we find them? And if they come from calculations in their own right, how do we pull off that arithmetic?

Actual cost (AC)

The simplest and most common variable in these equations is actual cost (AC). This is arrived at by adding up all the costs incurred up to that point on your project. It includes direct and indirect costs such as labor, materials, equipment, overhead, and any other related expenses.

Budget at completion (BAC)

There’s no actual budget at completion (BAC) formula. The number is simply the total budget for the project at the start. There are multiple project estimation techniques for determining the BAC: three of them are analogous estimation, expert judgment, and parametric estimation.

Earned value (EV)

This is best understood as the budgeted cost of the work that’s been performed at a certain point. It doesn’t matter how much it really costs you to get there. Determining earned value (EV) is simple: You just multiply BAC by the percentage of the project that’s complete at that point.

(To be disgustingly technical about it, you sum the budgeted costs of each completed task, and the partial budgeted cost of partially completed tasks).

Planned value (PV)

On the subject of value, we need to talk about planned value (PV) because it’s necessary for a later calculation. You get it by multiplying the percentage of the project you expected to complete at that point by BAC. So EV is the actual position, and PV is where you wanted to be at that point in the project schedule.

Cost performance index (CPI)

The first index gives you an indication of the cost efficiency and financial effectiveness of your project. The way you calculate CPI is to divide EV by AC.

- A CPI value over 1 suggests that your project is performing well;

- A value of 1 means you’re on a budget, and

- A value under 1 confirms that your project has strayed over budget.

Schedule performance index (SPI)

The second index does a similar job on the schedule. It does so by comparing our progress to how far we had expected to have come at this point. And this is where the PV calculation comes in. You divide EV by PV to arrive at the SPI for your project.

- An SPI over 1 means your project is ahead of schedule;

- A value of 1 suggests you’re bang on schedule, and

- A value under 1 means you’ve fallen behind schedule.

|

Estimate to completion (ETC)

The last variable we need to know can be confusing because one letter differentiates it from the main subject of this article. So it’s important to distinguish between them. ETC is the estimated cost of completing the project from this point forward. On the other hand, EAC is the estimated total cost of the project when we finish it.

The four ways to calculate EAC

There’s no single way to calculate your EAC. There are four formulas, and you must choose the one that makes the most sense in your current circumstances. Factors in play here are:

- The cost of acquiring the data needed in the formula.

- The data you have at your disposal.

- The current state of your project

But it’s the last bit that’s crucial in all four formulas. It’s an assessment of the current performance of your project – how much work is completed versus how much work you had planned to achieve by this point in your timeline.

Your chosen formula depends on where your project is now and what you think will happen from now on. Of the four shown here, pick the formula that best represents your assessment of what you think will happen for the remainder of the project, based on what has happened so far.

And, be prepared to explain what you did to determine the new EAC, and why.

EAC formula 1

The first formula is the most generic and the simplest one. It’s also the one you should use when your initial budget has proven inaccurate. So you press the reset button and re-estimate the balance of the project.

- EAC = AC + ETC

For obvious reasons, the formula is also known as the bottom-up EAC equation. You’re simply adding the actual costs incurred at this point to a new estimate to complete (ETC) for the work that remains on the project.

To get the new ETC, you can use the bottom-up approach (or any of the other applicable methods). With bottom-up, you ask your team to re-estimate, along with you, each of their remaining tasks on the project in terms of effort, cost and duration.

Then, you simply add the individual estimates together for your bottom-up ETC. And lastly, you add the new ETC to your actual costs so far to get the new EAC.

An example using this formula

Let’s say you’re managing the implementation of a new ERP system for an external customer, and your budget for the project is $100,000. Your project team has completed 40% of the work but has already spent half the budget.

The actual performance has drifted away from the project plan, exposing your original estimates as flawed. Maybe another project was delayed, and all the expected resources weren’t available to you. As a result, the less experienced team needed 25% more time to do their work. You hadn’t budgeted for that, and now you still have 60% of the work to do.

Using the bottom-up method to work out your ETC, you and your team arrive at an ETC of $65,000 to complete the work remaining in the project.

- EAC = AC + ETC = $50,000 + $65,000 = $115,000.

This EAC calculation suggests that our project will cost 115% of what was originally budgeted.

|

EAC formula 2

The second formula is most appropriate when a project has under-delivered early, and you expect a lower level of future performance. So now you need to adjust your expectations to reflect better what happened in the past.

We need to bring your cost performance index (CPI) into the equation to do that. And that’s calculated using EV, so we must use three formulas to arrive at our EAC.

- EV = BAC * % complete

- CPI = EV / AC

- EAC = BAC / CPI

Back to our example

Let’s calculate those values in the context of the ERP implementation example we’ve already outlined.

- EV = BAC * % complete = $100,000 * 40% = $40,000

- CPI = EV / AC = $40,000 / $50,000 = 0.8

- EAC = BAC / CPI = $100,000 / 0.8 = $125,000

So, according to this EAC calculation, the entire project will cost 125% of the original budget.

EAC formula 3

The third formula looks at your dilemma from a different point of view. It acknowledges that past performance was poor, but it expects you can improve performance levels for the remainder of the project. For that reason, it calculates EAC by relying on rates that were in the original budget forecast for the project.

- EAC = AC + BAC – EV

Using formula 3

We’ve already calculated EV for formula 2, so we can just plug the numbers into our working example project and see what happens.

- EAC = AC + BAC – EV = $50,000 + ($100,000 - $40,000) = $110,000

Of course, this result relies on us getting back on track. And if we fell off it because of resources that weren’t previously available, we need to get those resources back into harness to achieve this EAC. But stakeholders might be happier with this calculation, given that it’s only a 110% premium on the original project budget.

EAC formula 4

The fourth formula is applicable in situations where you’re running over budget AND behind schedule. It factors CPI and schedule performance index (SPI) into the calculations because they’re expected to influence the remaining project work.

We’ve already worked out CPI, but we’ll now have to calculate SPI for this formula, which relies on another variable we haven’t put a number to yet: PV.

- PV = % planned completion * BAC

- SPI = EV / PV

- EAC = (AC + BAC - EV) / CPI x SPI

Plugging the values in

If we take this to its logical number-crunching conclusion, this is what we get.

- PV = expected % complete * BAC = 50% * $100,000 = $50,000

- SPI = EV / PV = $40,000 / $50,000 = 0.8

- EAC = ($50,000 + $100,000 - $40,000) / (0.8 * 0.8) = $110,000 / 0.64 = $171,875

Your stakeholders will take one look at this 172% of planned project costs and will want to have some very serious conversations.

|

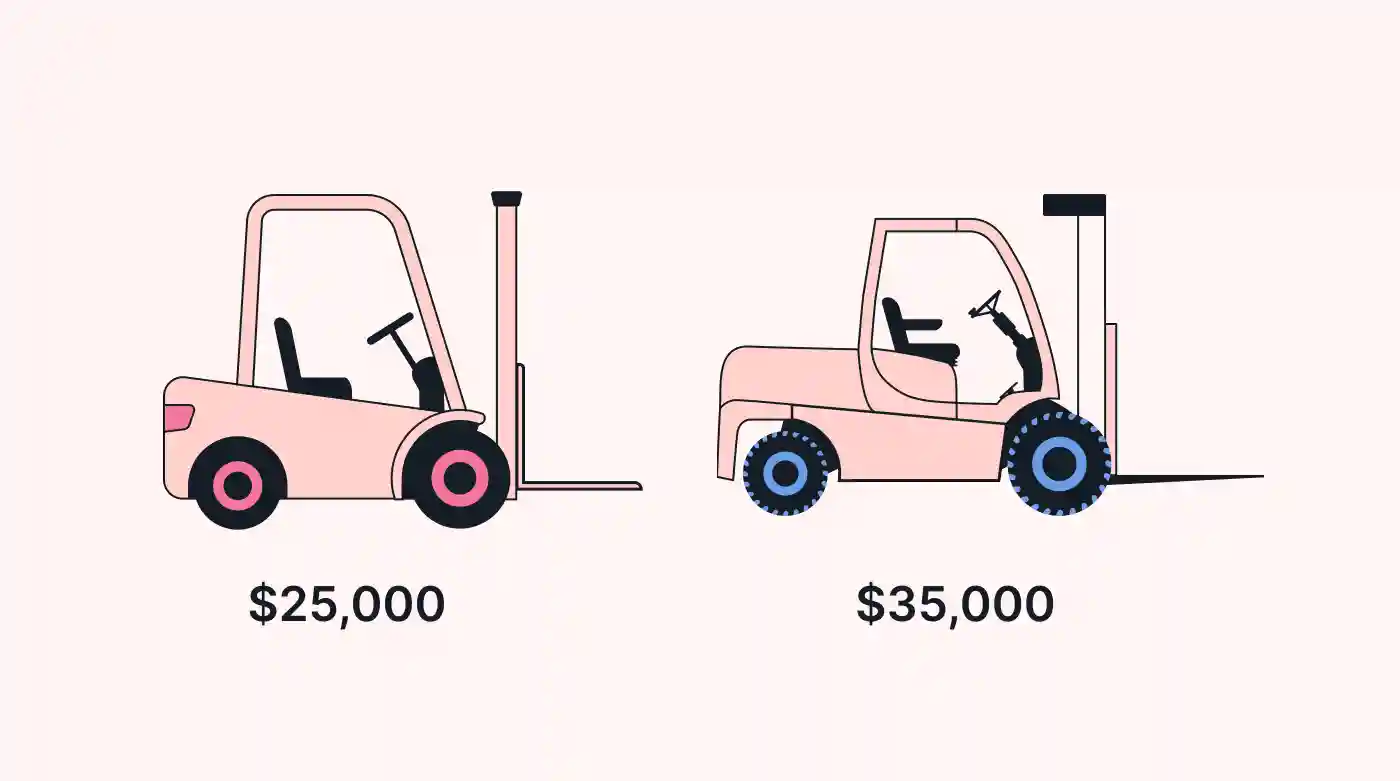

The other EAC

You may have seen the EAC acronym before, but in a different context. There’s another formula using the same moniker: equivalent annual cost. It’s used to determine how much it’ll cost you per year to own, operate, and maintain an asset over its entire life.

This EAC is often used for capital budgeting or determining whether leasing or purchasing an asset is the better option.

It’s all about the data

Any manager will tell you that formulas are great but utterly useless without the data you need to plug into them. The tricky bit for EAC is making sure you have data, planned and actual, for every task in the project.

Not only does that let you track actual costs against planned costs; it also helps you refine your forecasts for the rest of the project. You must store that data somewhere. Project managers have used spreadsheets or project management tools with that capability.

Putting your project in Motion

However, those tools can be cumbersome for scheduling tasks and resources on a project. That’s where you need a tool like Motion’s Project Manager app and its intelligent calendar.

Not only does it offer a centralized platform for sharing your project data with your team, but AI powers it, and it:

- Automatically reprioritizes tasks when priorities change or new urgent tasks arise

- Schedules work in your team member’s calendars

- Builds a custom schedule for every team member

So no one has to figure out when to do what, whether it’s project tasks, meetings, or other appointments.

And the best part is the automation. You define your tasks, dependencies, resources, priorities, and deadlines and assign resources. You and your team define their available time. Motion will automate scheduling, prioritize tasks, track progress, and more.

If you’re not using it yet, give it a whirl by registering for a 7-day free trial today.

After 40-odd years of working in technology, project management, media, and marketing, Brian's career and growth journey has exposed him to a wide range of niches. He brings this breadth of knowledge and expertise in his content work through enriched storytelling and original concepts that make SaaS content engaging and accessible for readers of all stripes.