Wish your team were more efficient?

The reality is that when processes aren’t optimized, organizations can run into some nasty stumbling blocks, such as drained resources, thwarted growth, and diminished team morale.

While there are plenty of corrective strategies out there, few have the simplicity and effectiveness of PDCA.

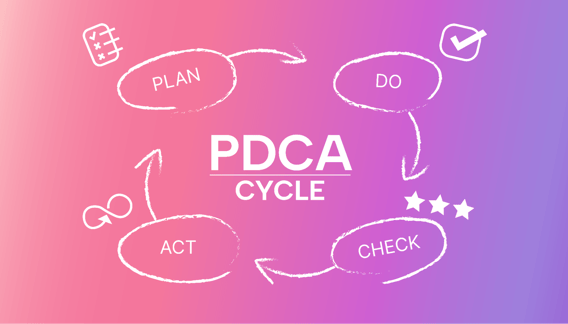

PDCA stands for Plan-Do-Check-Act. It’s a four-step model for optimizing processes or testing changes.

In this article, we dive deep into what PDCA is all about and how you can use it to help your organization reach its goals faster.

What is PDCA? A brief overview

PDCA is a cyclical, step-by-step approach used by businesses for continuous improvement.

It’s a process that includes the following stages:

- Planning: Identifying a problem and developing a strategy to address it

- Doing: Executing that plan and carrying out any strategies

- Checking: Assessing the results and analyzing the data or feedback

- Acting: Taking corrective steps to refine business processes or systems

But PDCA is more than just a process. It’s a philosophy that guides how an organization operates. The beauty of it lies in its simplicity, adaptability, and iterative nature.

It’s important to follow through with each stage. A common problem is to rush through the “Check” phase and then skip straight to “Act.”

For example, a retail chain with declining sales might rush into discount strategies or marketing pushes. But, without first conducting a comprehensive analysis, these actions may not reach the root cause of the problem. As a result, the issue could resurface later — or even amplify.

Where does the PDCA Deming cycle come from?

The origins of PDCA go back to the early 20th century. Walter Shewhart, the father of statistical quality control, pioneered it.

However, it was Dr. W. Edwards Deming, an eminent statistician and professor, who popularized the method and expanded its use beyond manufacturing. He recognized how universally applicable PDCA is and championed it across various sectors.

PDCA has since evolved and proliferated across different fields. Today, the following industries (and more) are putting its principles to use:

- Education

- Digital marketing

- Urban planning

- Healthcare

When should you use PDCA?

The following situations are ideal for employing PDCA:

When your goal is continuous improvement

If you’re striving for consistent growth and enhancement, PDCA provides a clear roadmap. It’s all about getting better, little by little.

When facing complex challenges

The iterative process of this methodology allows businesses to experiment, assess, and refine their strategies. This makes it ideal for tackling multifaceted problems.

When implementing new processes

If you’re introducing a system or procedure, you can test and tweak it with PDCA before issuing a full-scale rollout. This leads to a smoother transition and reduces hiccups.

When adapting to change

PDCA aids in agile responses in dynamic business landscapes. It allows your organization to pivot effectively, mitigating the risks that come with abrupt market shifts.

When cultivating a proactive culture

PDCA instills a proactive mindset if you want to go from reactive firefighting to forward-thinking strategies. This helps create a culture of pre-empting challenges and fostering innovation.

A step-by-step guide to PDCA

Let’s dive deeper into each step in PDCA.

Plan: The preparation phase

It’s important to understand your problem before deciding what your solution will be. This stage isn’t just about recognizing what the problem is but also why it’s happening.

Is it a surface issue, or are there deeper underlying factors? For example, if sales are declining, is this due to reduced market demand, aggressive competition, or an internal problem?

Actionable tip: Employ tools like the fishbone diagram to perform a root cause analysis.

Once you clarify the problem, set clear objectives. This step is essential since it determines how you’ll measure the effectiveness of your solutions.

Investing in the preparation phase paves the way for smoother execution down the line. After all, the foundation of every successful initiative is a solid plan.

Enlist your team for collective brainstorming and collaborative sessions to give you a comprehensive view of the source of your problems and help you apply solutions.

Ask your team the following questions during the “Plan” stage:

- What is the exact problem we’re trying to solve?

- Why does this problem exist?

- What are our objectives, and how will we measure our success?

Do: The implementation phase

Once you’ve planned meticulously, it’s time to bring your ideas to life. In the “Do” phase, you’ll put your plans into action.

But it’s not just about activity. You should document every move thoroughly, as you’ll need that data in the next phase.

Actionable tip: Make sure all stakeholders understand their roles clearly. Use tools like Gantt charts to track your progress.

This second step builds off your hard work in the first. For example, if you found a production bottleneck, depending on the cause, you might train staff or introduce new equipment.

Ask your team the following questions:

- How can we ensure the plan is executed as intended?

- Are all team members clear on their responsibilities?

- How will we document our actions and outcomes?

Check: The evaluation phase

After you’ve set your plan in motion, it’s time to analyze your results. Evaluate whether things are panning out as expected, and if they’re not, determine the reason for the discrepancy.

Be honest with the results you find. Scrutinize those outcomes against the benchmarks you decided on during the “Plan” phase.

Actionable tip: Use performance dashboards to visualize your results and spot anomalies.

Remember, it’s not just about gauging successes but also understanding failures. Your missteps contain valuable insights into how you can improve.

For example, if you implemented a new marketing strategy, you can evaluate whether you achieved the desired increase in leads or sales. And if you didn’t reach your goal, you can learn from what transpired.

Ask your team the following questions:

- Did we meet, exceed, or fall short of our objectives?

- What unexpected outcomes did we encounter?

- What can we learn from the deviations in our results?

Act: the adaptation phase

The final phase in the cycle is where tweaks and refinements come into play. Armed with your insights from the previous step, you can adjust and recalibrate your operations.

If things went according to plan, standardize the process and think about driving more success in that area. If you ran into problems, make the necessary changes to get back on track.

Actionable tip: Foster a culture in which you welcome feedback. Hold regular debriefing sessions to discuss what went well and what needs adjustment.

The “Act” phase is dynamic. It’s about adapting with wisdom and flexibility.

For example, if a new product feature didn’t resonate with users, maybe its functionality or presentation could be modified.

Ask your team the following questions:

- How can we incorporate what we’ve learned into future initiatives?

- If we achieved our goals, how can we further optimize our processes?

- If we fell short, what corrective actions are necessary?

Why is the PDCA cycle important?

PDCA isn’t just a methodology. It’s a transformative tool that companies use for consistent growth and innovation.

Let’s break down the inherent benefits of this approach.

Efficiency

Businesses can use the PDCA cycle to eliminate wasteful processes and sharpen their overall efficiency.

That’s important since inefficient processes are extremely common in the workplace. According to research by Formstack and Mantis, over half of workers spend two hours per day on repetitive tasks that could be handled by automation.

With PDCA, redundant processes can be spotted and streamlined, freeing up valuable team hours for more strategic endeavors.

Consistency

The iterative nature of PDCA can help create reproducible results and consistent outcomes.

Imagine a coffee shop that brews the perfect cup one day and a mediocre one the next. PDCA ensures consistent quality.

A case in point is Starbucks. Their commitment to delivering the same taste and experience globally is backed by continuous review and refinement processes, similar to PDCA.

Team empowerment

PDCA fosters a culture of shared ownership by engaging the entire team in planning and evaluation processes. Engaging employees is crucial to getting the performance you want.

Gallup’s 2022 employee engagement survey found that less than a third of employees are engaged in their work. PDCA can help to reverse that trend and empower your team.

Risk mitigation

The proactive nature of the PDCA process allows businesses to foresee challenges and mitigate risks before they escalate.

Companies like Boeing, with their rigorous pre-launch testing and evaluations, exemplify this benefit. Simulating potential flight issues beforehand helps to ensure the safety and reliability of their passengers and staff.

Overcoming PDCA challenges

Understanding the misconceptions and limitations that can get in the way of your PDCA approach can help you mitigate those challenges. We’ll cover common myths and limitations in this section.

Debunking common myths

Here are three common myths about PDCA to be wary of:

Myth #1: PDCA is too time-consuming

Think of PDCA as spending time now to save time later. It’s an investment. For example, Turner Construction has an extensive preconstruction approach. While they spend time performing this preconstruction, doing so ultimately helps them reduce delays and cost overruns.

Myth #2: PDCA is too complex

Apple, which is known for its simplicity, uses a methodology similar to PDCA for its product development. It focuses on clear stages, from conception to review, to distill complex design challenges into structured steps.

PDCA functions similarly, making daunting problems less intimidating by breaking them down into more manageable pieces.

Myth #3: PDCA is too disruptive

Some believe that PDCA can disrupt existing workflows.

However, when implemented correctly, PDCA seamlessly integrates with ongoing processes — refining rather than disrupting them.

The limitations of PDCA

These are three common limitations to the PDCA approach:

1. Over-reliance

Businesses should avoid using PDCA as their only problem-solving tool. It works best when used with other methodologies and tailored to specific challenges.

2. Over-analysis

PDCA’s iterative nature can lead to analysis paralysis. It’s crucial to strike a balance between evaluation and action, as this ensures that the cycle moves forward.

3. Oversimplification

PDCA requires customization. Applying a one-size-fits-all approach might lead to less-than-ideal results. The framework should fit each organization’s unique context and challenges.

The power of PDCA: How to get the best results

Unlocking the potential of PDCA depends largely on its execution. Here’s how to reap optimal results and ensure this approach is done right:

Ensure effective implementation

The first step of implementation is to set clear objectives. If you don’t have a distinct destination, it’s easy to steer off course. Establish specific goals and KPIs at the outset so that you carry purpose and direction with you through every step.

Second, collaborate closely with your team. Bringing diverse perspectives to the table helps to enrich the process, leading to more comprehensive and innovative solutions.

Lastly, set up regular review points. For example, during product development, you could hold biweekly review meetings. Mini-reviews throughout the process will help keep you on track to achieving your goals.

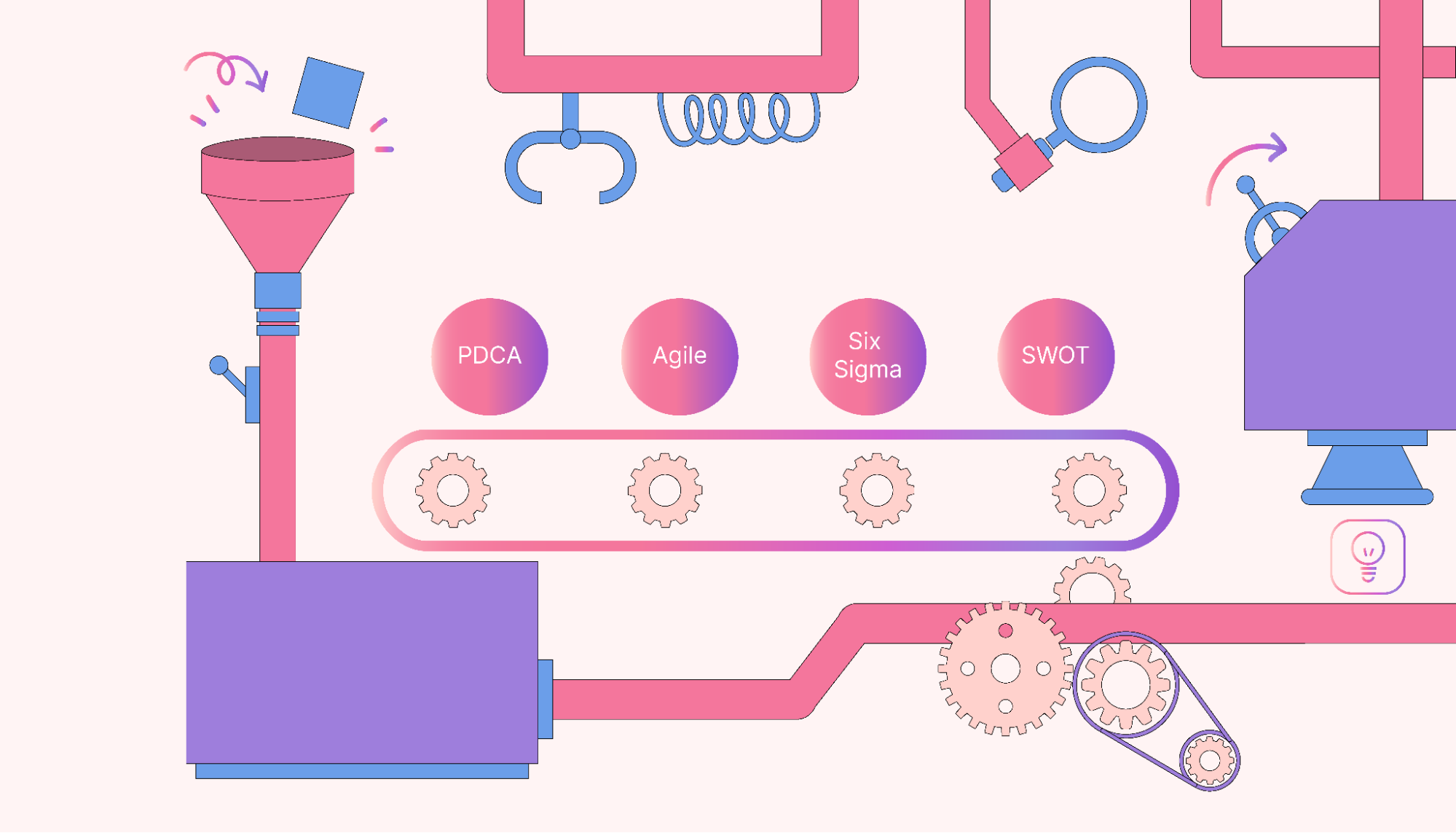

Synergize with other methodologies

PDCA is versatile, and using other tools can amplify its strength.

For instance, General Electric combined Six Sigma and its defect detection with PDCA’s continuous improvement, saving the company billions.

Teams can also incorporate Agile into their PDCA cycle to make for a process that’s not just iterative but also adapts rapidly.

Another possible combination would be to use a SWOT analysis during the planning phase to provide a detailed understanding of strengths, weaknesses, opportunities, and threats. This will give your PDCA process deeper insights.

Case study: How Toyota uses PDCA

Toyota isn’t just a well-known car manufacturer — it’s also arguably the most famous proponent of PDCA.

PDCA has been a cornerstone in maintaining Toyota’s reputation for high-quality vehicles. The global automotive giant’s reputation for churning out top-notch vehicles isn’t down to luck; it’s a result of Toyota’s unwavering commitment to continuous improvement, with PDCA right at its heart.

Toyota is constantly refining its processes. That makes it:

- More productive

- More efficient

- More aligned with drivers’ needs

For example, their assembly lines have a tool called an Andon cord that allows any worker on the line to halt the production process if they notice a defect. The company can then evaluate and decide on a solution before moving forward. This system embodies Toyota’s dedication to quality and rapid response to issues.

Eliminate inefficiencies with Motion

Now that you understand the four-step approach of Plan-Do-Check-Act, you can put it to use in your company.

But PDCA isn’t the only tool you can use to remove inefficiencies. Motion’s powerful AI calendar app automatically populates your team’s schedules based on shifting priorities. Using it can save you an extra month every year.

With task management, project management, and a booking system, you can cover all your bases with one tool. Try Motion for free today!