As a business manager, you know time is money. Dealing with inefficient processes, insufficient resources, and unsatisfied customers eats up time and energy you don’t have.

That’s why a well-planned production schedule is crucial to the success of your business, whether you’re creating cars, cakes, or content.

This behind-the-scenes process is the heart of any production operation, orchestrating the seamless coordination between resources, tasks, and timelines. Efficiency ramps up as you maximize time and resources and deliver high-quality products to your customers by their deadlines.

Ready to maximize output like never before? Here’s our step-by-step guide to creating and implementing an efficient production schedule.

What is a production schedule?

A production schedule is a detailed plan that outlines the timeline and specific activities involved in producing goods or services. It plays a crucial role in production management by helping businesses efficiently allocate resources and meet production targets.

A production schedule is like a to-do list and a calendar that a business uses to make things. It is a high-level plan that shows what needs to be done, when it should be done, how long it will take to complete each task, and what resources you need at every stage.

With a production schedule, you maintain adequate supplies, manage time effectively, and deliver projects on time — satisfying your customers.

Production schedule example: A bakery

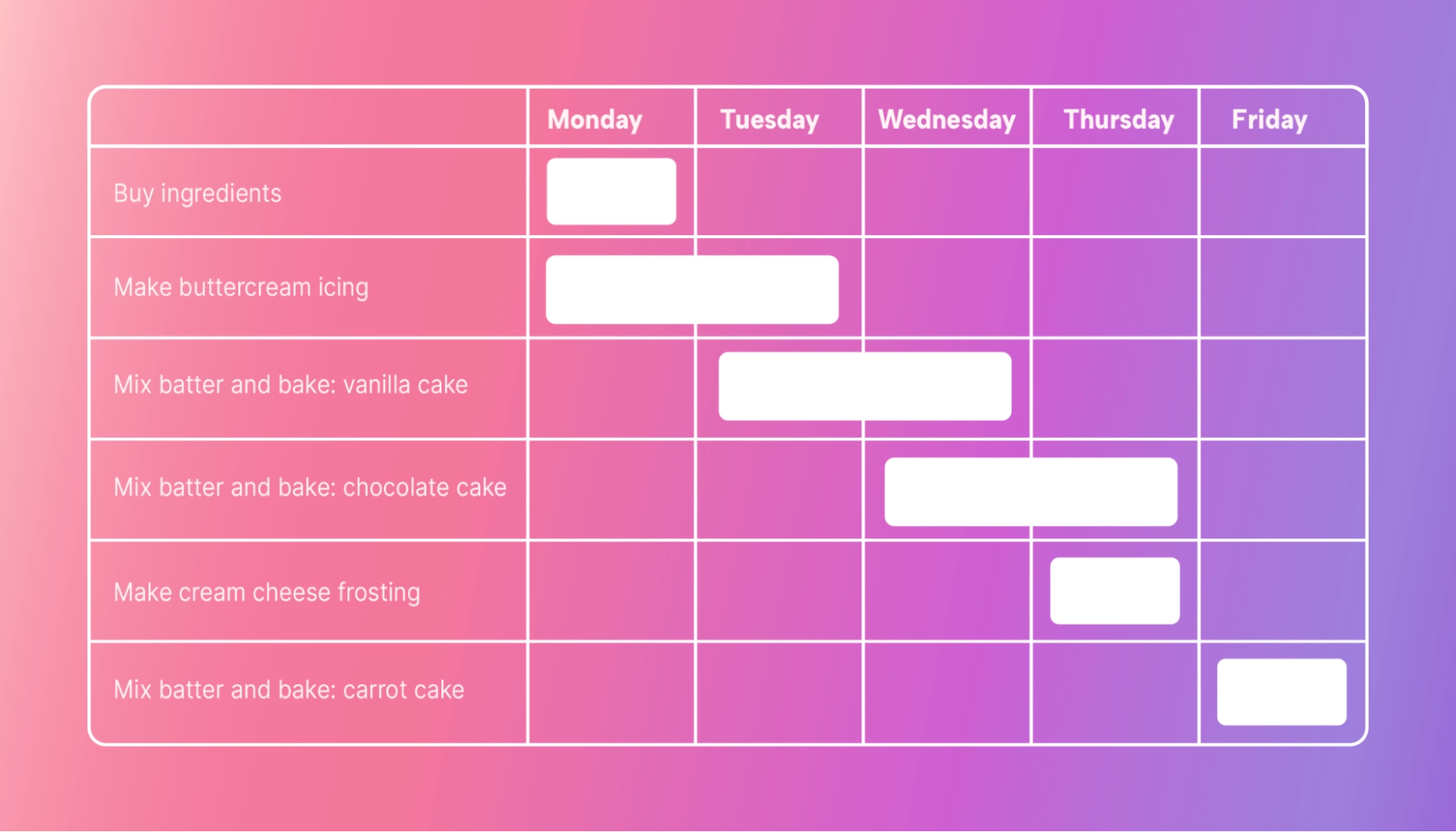

Bakeries use production schedules to map out the different steps and timings of baking and selling their products.

Here’s an example of a bakery production schedule:

- Source ingredients on Monday morning.

- Make bulk batches of icing on Monday afternoon.

- Mix the batter and bake the cakes on Tuesday.

- Ice and decorate the cakes on Wednesday morning.

- Put the completed cakes for sale on Wednesday afternoon.

If you sell multiple cake flavors, your production schedule must include the relevant steps for each type of cake. You might stagger some of the phases to keep your hands busy as you wait for other cakes to bake or cool down.

In this scenario, the production schedule helps organize the bakery and ensure everything happens smoothly. It tells the bakers and assistants what needs to be done and how long it will take, allowing them to plan their resources accordingly.

What’s the difference between production scheduling and production planning?

Production planning comes first and is often considered the initial phase of a production schedule. It involves determining the market demand for the product, the process needed to produce the product, the manufacturing metrics necessary for success, and the required materials, resources, and staff.

Production scheduling carries out the plan in greater detail. It outlines when everything needs to happen in the different stages of production and who is responsible.

Comprehensive schedules should also include backup plans and maintenance intervals to account for disruptions in production.

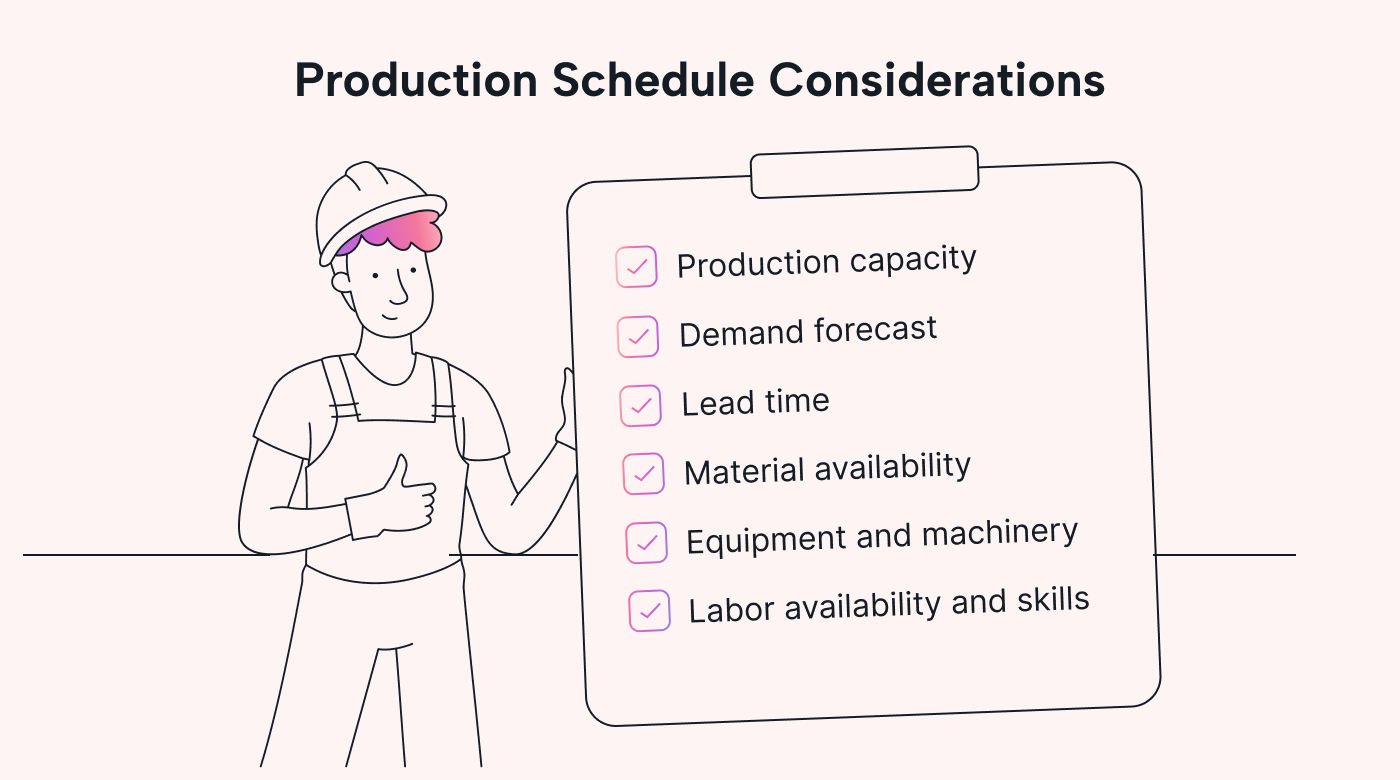

Considerations to make when creating a production schedule

A production scheduler designs a functional, optimal production schedule that considers all business constraints. It essentially bridges your customers’ wants and your business’s capabilities.

The production scheduler’s role usually falls within a team or project manager’s roles and responsibilities.

Since production schedules map out every step of the production process, you must have a well-rounded view of all the considerations you need to make before you can design a helpful schedule.

Here are just a few of these important factors:

Production capacity

How much can you produce within the given timeframe?

Production capacity is the maximum number of goods you can produce within a given timeframe. Establishing this number before creating your schedule is important, as it will affect the timeline for each production run.

Strong capacity management keeps your schedule on track and helps you avoid issues like underproducing or overworking your team. Schedulers must also consider capacity constraints, including worker absences, inventory shortages, and equipment malfunctions.

Demand forecast

How much demand do you think there will be for your product or service?

Estimating how much demand there will be for your product or service will help you to plan how much to produce at each step of the process. You can use past sales data, market research, and other information to make an educated guess.

Lead time

How long will the process take, from the raw material procurement to the final product delivery?

Lead time is the time it takes from ordering raw materials to delivering the final product. This factor significantly impacts the time it takes to complete each run, so make sure to consider it when creating your schedule.

Material availability

Do you have all the raw materials, components, and supplies you need?

Having all the items you need is vital to completing a run successfully. Unfortunately, only 22% of companies have a proactive supply chain, so most businesses struggle with material availability. So be sure to plan before starting a new run so you don’t run out of important material mid-way through production.

Equipment and machinery

Do you have the right equipment to manufacture your goods?

Make sure you have the correct tools and other equipment throughout the production schedule. Be sure to check that all of your equipment is functioning properly and that you have backups in case of breakdowns.

Labor availability and skills

Do you have the right number of people, and do they have the correct skills?

Having enough workers with the right skills helps ensure that production will run smoothly and finish on time.

How do you determine if you have enough team members to complete the job on time?

While experience matters, talking to others in the field and gathering knowledge directly from your employees can also be helpful.

What goes into a production schedule?

Creating a production schedule takes time and effort, but it is worth ensuring you meet your long-term goals.

Here’s what you need to include in your production schedule for timely delivery and quality outcomes:

Tasks and activities

This is the first and most crucial step in creating a production schedule.

List all the tasks involved in the production process, from procuring the raw materials to packaging and product delivery. That way, everyone involved understands the expectations.

A good task manager helps you keep track of everything as you go along. Check out Motion’s Task Manager to help you stay on top of your tasks.

Sequence of operations

Once you’ve listed the tasks and activities, determine the order in which you need to execute them. Logically arranging them helps keep the production process moving smoothly and frustrating delays at bay.

The sequence of tasks must consider task dependencies and mini-deadlines. The optimal task sequence results in the fewest or briefest pauses between individual tasks and stages.

Timeframes

Set start and end dates for each task or activity in the production schedule to keep everything on track.

Clear deadlines are essential to meeting production times. They keep everyone in the loop when it comes to expected delivery dates and assignments.

Resource allocation

This phase of creating a production schedule involves giving the right people the necessary resources at each stage.

Using skilled labor or productivity tools ensures everyone can do their tasks efficiently.

Constraints and considerations

It’s unlikely that your production schedule will go smoothly. Even the most comprehensive plan can encounter hurdles, including unforeseen challenges or delays, at any time.

List constraints and considerations that could potentially derail your production schedule. These could relate to internal matters, like budget or worker availability, or external factors, like changes in legal requirements, fluctuations in demand, or market conditions. Incorporating extra time to account for any unexpected events is a good idea.

Benefits of creating a production schedule

Creating a production schedule has many benefits. Planning ahead lets your team accomplish more in less time.

Efficient use of resources

Up to 20% of every dollar spent in the manufacturing industry is wasted. A well-designed production schedule allows for efficient resource allocation, reduced wastage, and more cost savings.

Improved productivity

A production schedule acts as a product roadmap that everyone on the team can follow to achieve a common work goal. With clearly defined roles and deadlines, team members know what’s expected of them and can work more efficiently and productively.

On-time product deliveries

With a work schedule in place, your team will know exactly when each product will be ready for market. This can help you set realistic and achievable deadlines. Clever scheduling decisions also make your teams more resilient against potential disruptions.

Improved team alignment

When team members have access to a production schedule, they know each other’s workloads and can plan their work accordingly, preventing confusion and optimizing team productivity.

Using Motion to create a production schedule enhances team collaboration and coordination. A centralized task and deadline management platform keeps everyone aligned throughout production.

Opportunities for continuous improvement

Your production schedule can provide insights into what’s working and what isn’t.

Use this information to adjust and improve your processes so that you can gain a competitive edge with agile team members and real-time adaptability.

More satisfied (and return) customers

Delivering quality goods on time and in full helps you build a good reputation among your customers. As you build customer trust, this can translate to repeat business and more referrals.

When you prioritize timely delivery and top-quality products, you give customers a reason to return for more.

5 stages of production scheduling

Creating a clear and effective production schedule is easier when you break the process down into consecutive stages.

The five stages of effective production scheduling are as follows:

1. Planning

Effective production planning is vital to ensuring that your team knows where they’re heading and keeps everyone on the same page.

The planning phase includes processes like:

- Demand forecasting: Predicting customer demand by analyzing data and market trends.

- Capacity planning: Calculating whether the company can meet demand while remaining within the confines of your team’s availability, your equipment’s output, and your resource constraints.

Your long-term goal is to match your production capacity with the product’s demand. A well-structured project plan makes that possible.

Use your research to set realistic production goals, and then outline the company’s steps to meet those goals.

2. Routing

Routing involves identifying the operations required to produce each product, the resource and material requirements for each step in the production process, and the most efficient production path. Carefully analyze every step involved, from gathering the raw materials to the product’s completion.

This phase includes inventory management and material planning, both of which involve determining how much of each material you need and when you need it.

The goal is to develop a streamlined production flow that minimizes waste, maximizes output, and meets your product quality standards.

Routing is the production scheduler’s version of choosing the fastest route home on Google Maps. Planning considerations include material availability, equipment capacity, and workforce availability, just like the map’s algorithm considers toll gates, accidents, and traffic.

3. Scheduling

Essentially, this step involves creating time frames to ensure that each stage of production is completed on time with as little idle time between the stages as possible.

Scheduling decisions must include assigning start and end dates for each operation, assessing the production capacity, and ensuring resource availability.

Keep the process running smoothly (thus avoiding bottlenecks and delays) by scheduling regular order intervals.

4. Dispatching

Next, work orders are issued to the production team, and tasks are assigned to individual workers.

At this stage, it’s essential to ensure that each worker knows what they’re supposed to do during the process. Clear communication between team members is crucial to ensuring that everyone works effectively.

5. Execution

The fifth and final stage is the execution and delivery of products to clients.

At this stage, the team follows the production plan according to the schedule and work orders. You monitor progress and adjust the manufacturing schedule to ensure everything runs smoothly. The goal is to run an efficient production process, meet set quality standards, and produce timely output.

Part of execution is maintaining the production schedule, which involves real-time monitoring and adjustment. Track what’s working and what isn’t, and use this real-time data to make quick adjustments and inform any changes you make to the process next time.

Keep your production schedule on track with Motion

A production schedule can make or break the success of any project. Luckily, there’s an easy and effective way to streamline the production scheduling process: Motion.

Motion automates the process of production scheduling, eliminating the tedious and time-consuming aspects of the job. With it, you can easily keep your team members informed and on track, ensuring that each step of the production process is completed on time and within budget.

Whether you’re new to project management or a seasoned professional, Motion can help you improve your operations.

So why not give it a try today? Sign up for a free 7-day trial.

Jodi Monroe is a content writer and blogger in the SaaS space. When not at her laptop, she’s planning her next travel adventure.